Lectus Technocast Pvt Ltd

Process Overview

Investment Casting Process

- The Dies Tools (Dies/patterns) are manufactured using CAD/CAM software.

- We are providing extended support in developing new parts of Clint with all our development team in line with requirement.

- Injection and production of wax pattern from Dies (Patterns/tools). All Wax patterns are 100% dimensionally checked.

- The Wax pattern after forming the tree or cluster undergoes the ceramic coating process. This process is done in temperature and Humidity controlled rooms, so that best dimensional accuracy and excellent surface finish is achieved.

- After completing the coating process, the wax is removed by de-waxing process, which is done by putting the ceramic mould in the hot bath of wax.

- The Ceramic moulds are baked at temperature ranging from 900°C to 1150°C depending on the geometry and size of the casting. The molten metal is then poured in the baked ceramic moulds.

- The casting then undergoes fettling and finishing process such as Gate Cutting, Gate Machining / grinding, Sand Blasting, Shot Blasting, Leaching, Deburring etc.

- The coating then undergo the Heat Treatment as Per the material specifications.

- Heat Treatment graphs are cycles are recorded and documented.

- All castings are subject to 100% visual inspection.

- All critical dimensions are 100% inspected before packing and shipment.

- We are also providing castings with machining.

- Castings can be also supplied with various type of finishing such as passivation, Electro-polishing, Blackening, powder coating, shot blasted, Glass bead blasted.

5 Manual Press and One Auto Press With Central Wax Filling System

This is C – frame, Vertical wax injection machine. The die/tool is placed on the work table. The Down stroking injection Nozzle is brought in contact with the injection port of the die. Wax is injected top-down into the die. This machine offers full pressure, flow – rate, temperature and dwell time controls..

Automated Wax Injection Press

12 Ton 4 Pillar Type Vertical Downward Clamping, Horizontal Injection adjustable nozzle In Vertical Axis 4-Pillartype, Semi- Automatic Hydraulic Wax Injection Press.

Runner Dipping M/C & Wax Melting Machine

The Runner dipping machine tank is used for preparation of wax for its subsequent feeding into conditioning tank. The melting tank is made of S.S.-304 and heated all around by low current density electrical heaters. Small pieces of wax are Loaded from the top and heaters switched ON. It may take a long time to melt all the wax if the machine is started from cold

Wax Conditioning M/c (200Kg)

The wax-melting tank is used for preparation of wax for its subsequent feeding into conditioning tank. The melting tank is made of S.S.-304 and heated all around by low current density electrical heaters. Small pieces of wax are Loaded from the top and heaters switched ON. It may take a long time to melt all the wax if the machine is started from cold.

Wax Extrusion Press

Hydraulic Ram Pressing a Wax Billet against a Heated Die which in turn produces Extruded Wax Shapes. Hydraulic Force for Extrusion is 15 T. This machine extrudes wax billets into long lengths of various preferred cross sectional sizes. The wax billet’s can be fed at ambient room temperature of 25C to 30C or may be warmed to about 40C. Filled and Unfilled waxes may be processed. It is also possible to extrude hollow tubular sections with appropriate optional tooling.

Hot Plate

The injection moulded wax patterns are assembled into trees or clusters on the Hot Plate.

High Speed Slurry Mixer Machine

This High Speed Mixer Machine has the feature of frequency conversion speed-regulating, air-powered elevating, anti-explosion and seepage-proof. They can work continuously, disperse the materials very well and can be installed easily.

Slurry Coating Machine

The prepared slurry from the slurry mixer is feed to the slurry pot. This machine is also known as dipping pot, as wax trees are dipped into slurry held in this pot. This slurry is kept under continuous stirring throughout its use, in order to prevent the setting or separation of heavier refectories used in the slurry.

Horizontal Rainfall Sander Machine

In the shell building process, after dipping the cluster in the slurry, they have to be coated with sand. The machine produces uniform sand rain in which the slurry dipped wax cluster is manipulated to obtain a uniform coating of the refractory particles on the cluster.

Sand Fluidised Coating Machine

The FBS is designed to generate uniform fluidizing in the sand to maximize covering efficiency. The FBS has been ergonomically designed to maximize worker comfort. Designed for silent, smooth and trouble free operation.

Dust Collector For Sand Fluidized Coating Machine

Cartridge collectors use perforated metal cartridges that contain a pleated, nonwoven filtering media, as opposed to woven or felt bags used in bughouses. The pleated design allows for a greater total filtering surface area than in a conventional bag.

Wax Boiling Tank - 1000 Liters

Recovery for reuse after Dewaxing is simpler boiling off the water, filtering off the (ash) sediments – as can be done

Dewaxing Autoclave Machine

Shells are place in a trolley mounted baskets and the baskets is rolled into the autoclave. The pressure and temperature raised to required levels and held for some time. Then the steam is closed and the exhaust is opened. Once the autoclave pressure drops fully, the wax drain valve is opened. The door is opened and the de-waxed basket of shells is rolled out and a fresh batch is loaded. The drained wax is cast into slabs.

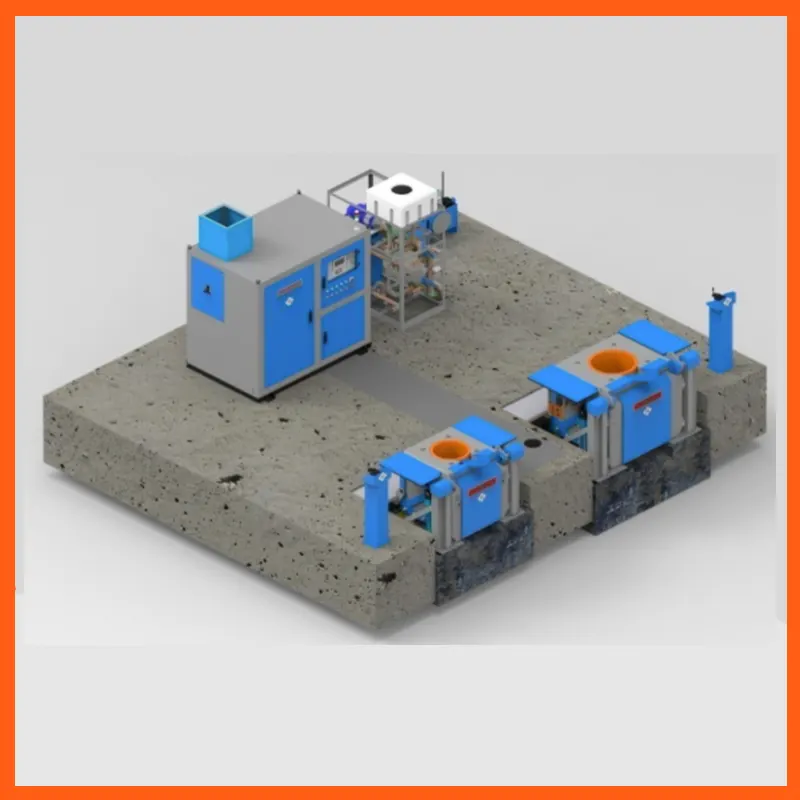

Induction Furnace

250KW/1KHz, 6-Pulse “ENERGY +” IGBT based Solid State Power Supply Unit with 150KG & 300KG Crucibles of Melting Furnaces together with Electrical & Cooling Systems.

Vibrating Knockout Machine

Once the shells are poured and cooled, the shells ceramic has to be removed to reveal the poured castings. The breaking off of the shell is done on a pneumatic knockout machine. Here about 80% to 90% of the shells material is removed quickly and efficiently without in any way damaging the cast parts.

Abrasive Cut off Machine

The cast components have to be cut-off at the in-gate from the main sprue or runner bar. The Abrasive gate cut-off machine is used for this purpose. The ACM provides for a quick clean cut and is cost effective to use.